Schenkzoola

Member

- Joined

- Jan 26, 2019

- Messages

- 5

Hi everybody, I recently purchased a Rav4 EV with 126,000 miles. This car had terrible drive unit bearing noise, so I took it upon myself to try to fix it.

ALL of the noise was caused by bearing failure, however taking it apart exposed a seal failure as well.

Three bearings were in bad shape. The motor bearings had axial play, and the gearbox pinion bearing had fretting on the outer race, indicative of shaft voltage.

Here is a google doc describing it: https://docs.google.com/document/d/1A6n0bkLowViFNtoD2bjzkL_IHk5RLS-mvYRUpe2qzGA/edit?usp=sharing

Please excuse the crudity of the document, I didn't have time to build it to scale, or to paint it.

Lots more pictures here:

https://photos.app.goo.gl/fUffopAvPV64R6kBA

This is my first experience working on an EV, and let me tell you, they are so much easier to work on than gas cars.

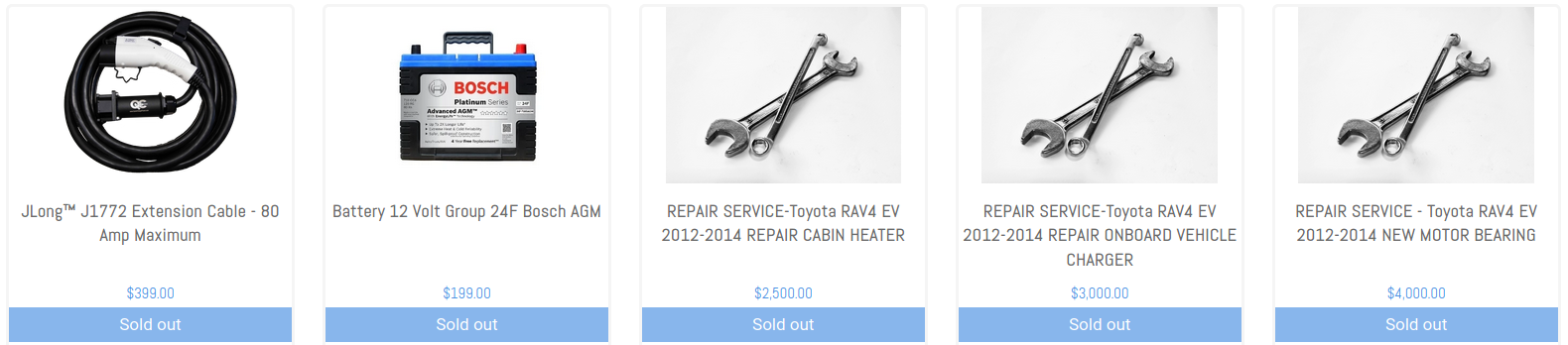

Since there are no drive unit service manuals or internal parts available from Toyota, or presumably Tesla, I would encourage others to share as much as you can about replacement pieces and procedures.

ALL of the noise was caused by bearing failure, however taking it apart exposed a seal failure as well.

Three bearings were in bad shape. The motor bearings had axial play, and the gearbox pinion bearing had fretting on the outer race, indicative of shaft voltage.

Here is a google doc describing it: https://docs.google.com/document/d/1A6n0bkLowViFNtoD2bjzkL_IHk5RLS-mvYRUpe2qzGA/edit?usp=sharing

Please excuse the crudity of the document, I didn't have time to build it to scale, or to paint it.

Lots more pictures here:

https://photos.app.goo.gl/fUffopAvPV64R6kBA

This is my first experience working on an EV, and let me tell you, they are so much easier to work on than gas cars.

Since there are no drive unit service manuals or internal parts available from Toyota, or presumably Tesla, I would encourage others to share as much as you can about replacement pieces and procedures.