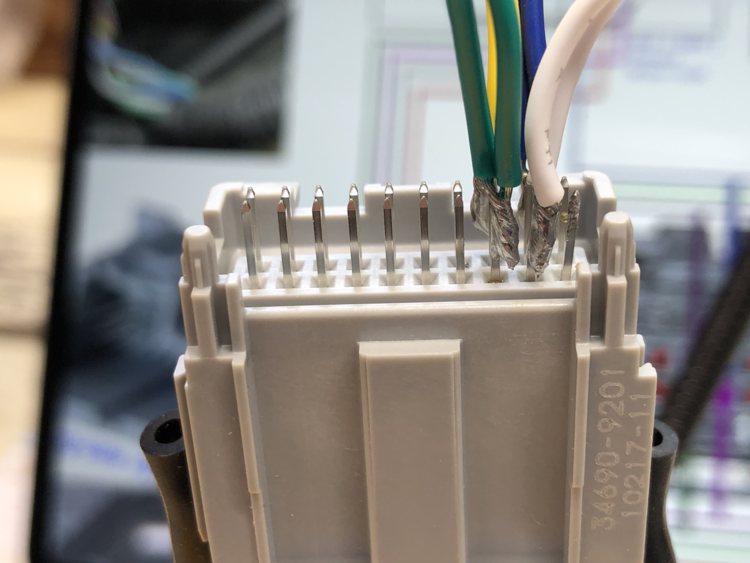

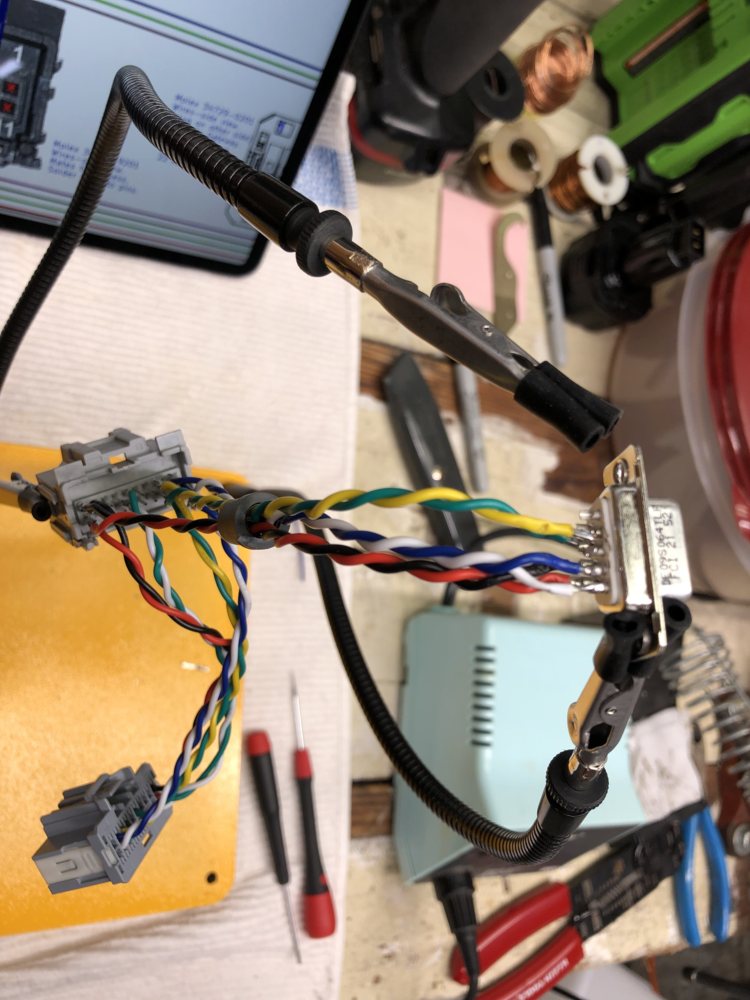

Tough installing heat shrink over two leads, then sliding down onto the pin after soldering. I'd have to use larger heat shrink than would fit well. This is all low voltage stuff, so any gap >.020" is fine, as long as the humidity stays reasonable.

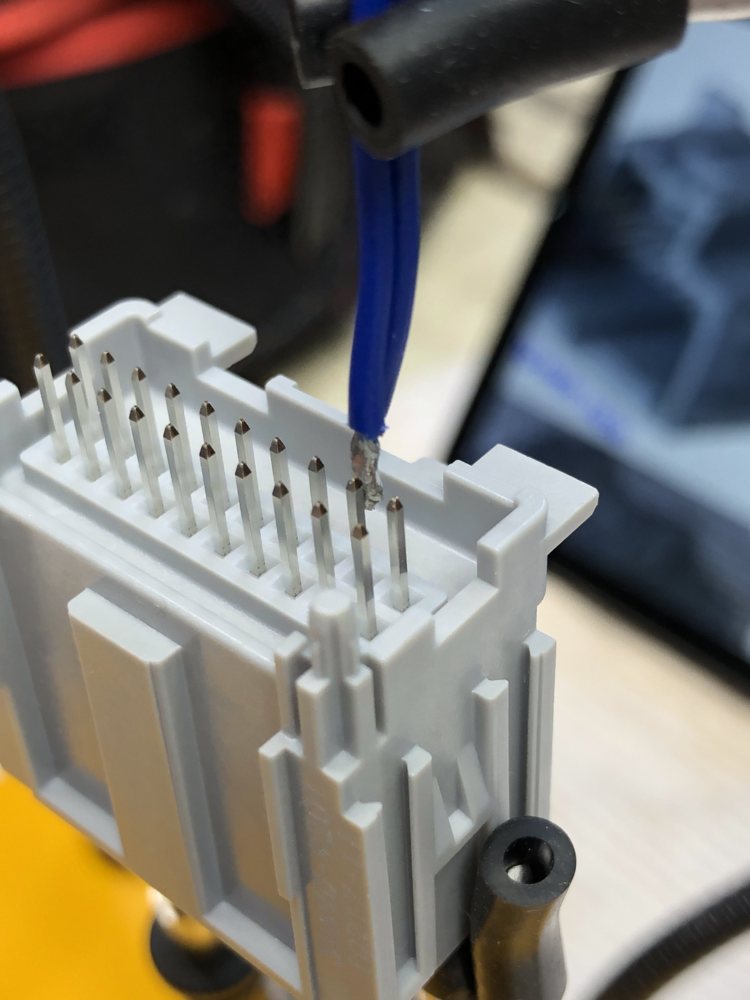

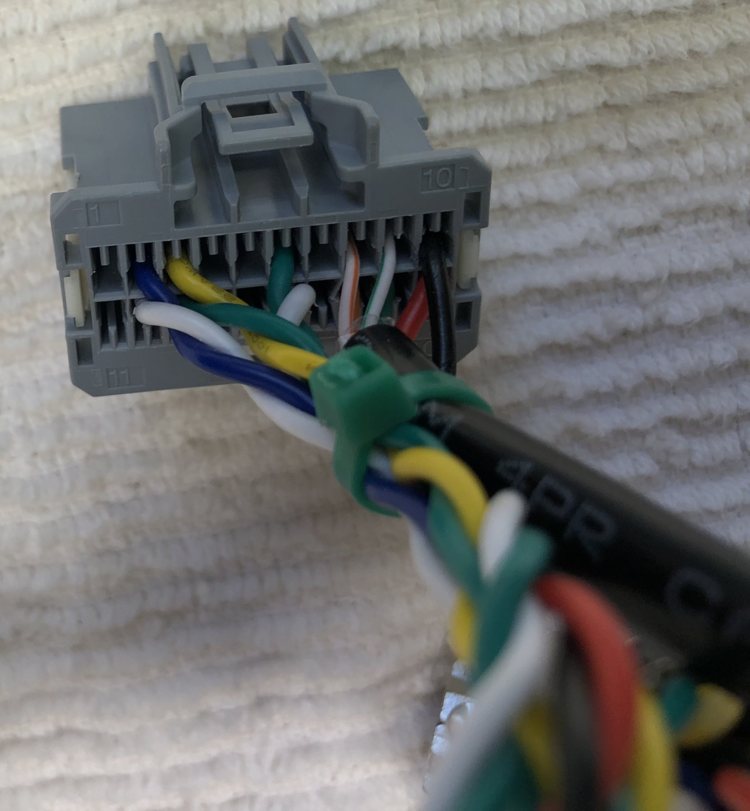

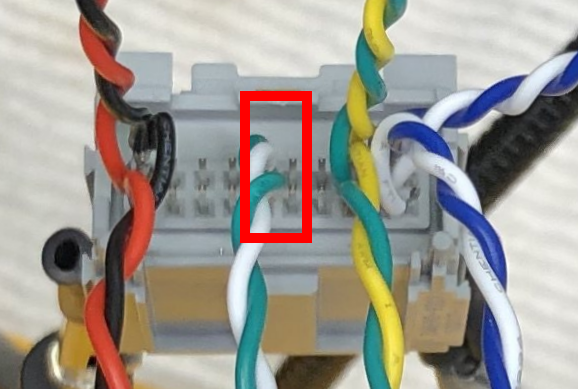

With proper nippers, a pin forest this sparse will be easy-peasy, once I nip off the unused pins. Then, on adjacent pins, I can bend them away from each other. I just could not find my nippers -- I just signed a lease and am moving residence -- and you can't really used gen-purpose side-cutters on this stuff, they're too large.

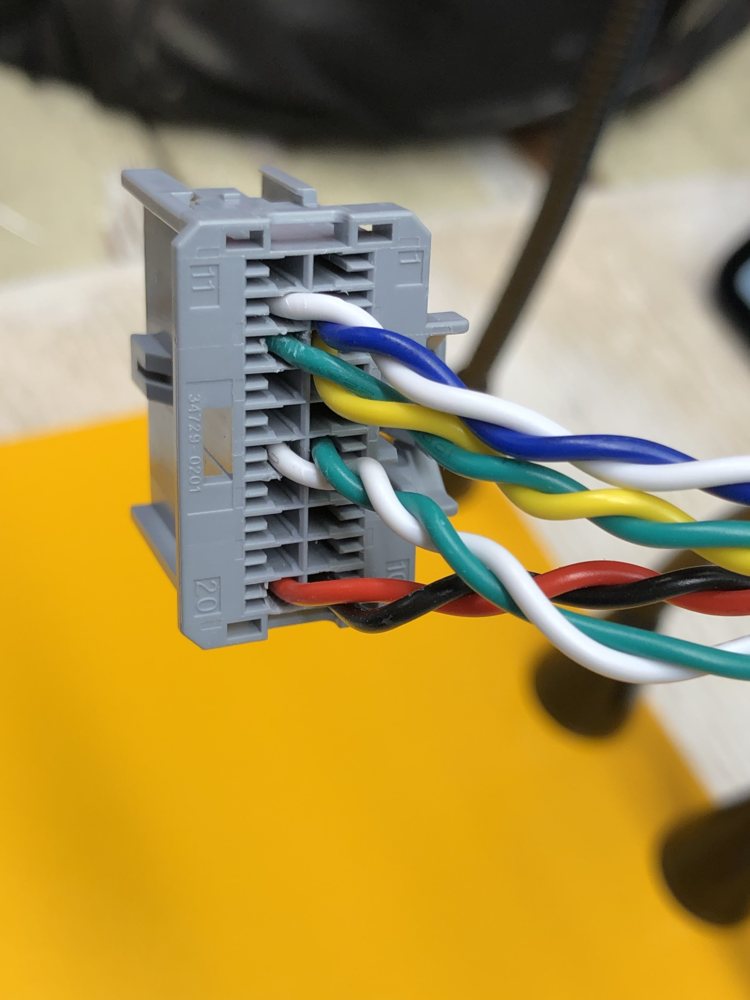

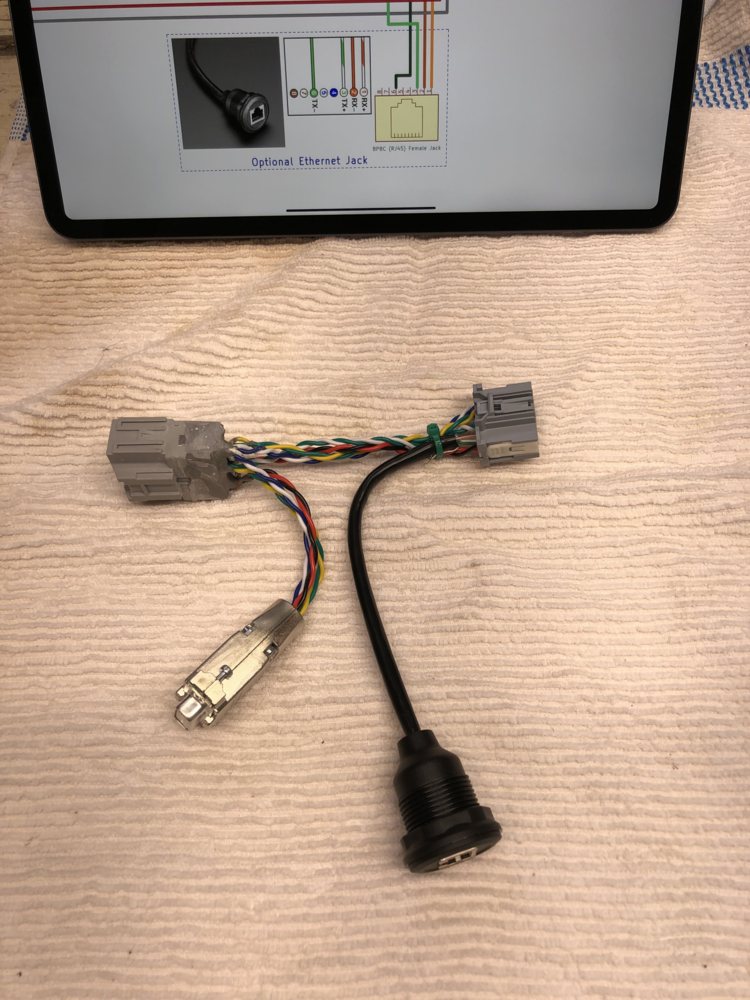

I don't mind epoxy, it's just that the electrical test is supposed to precede the potting, and I got it out of order again. Like soldering terminals and then remembering that I was supposed to feed through a housing first, or install heat shink first, or whatever. Happens to me all the time, esp. with interruptions.

Mouser forwarded to me a notice that the DE9 shell that I used has been discontinued by TE Conn.

shame, it's nice. I'll have to find a sub if I need another one someday. I used to buy metal shells like this by the bucketload . . . 25 years ago.

When you gonna draw up proper adapter boards?

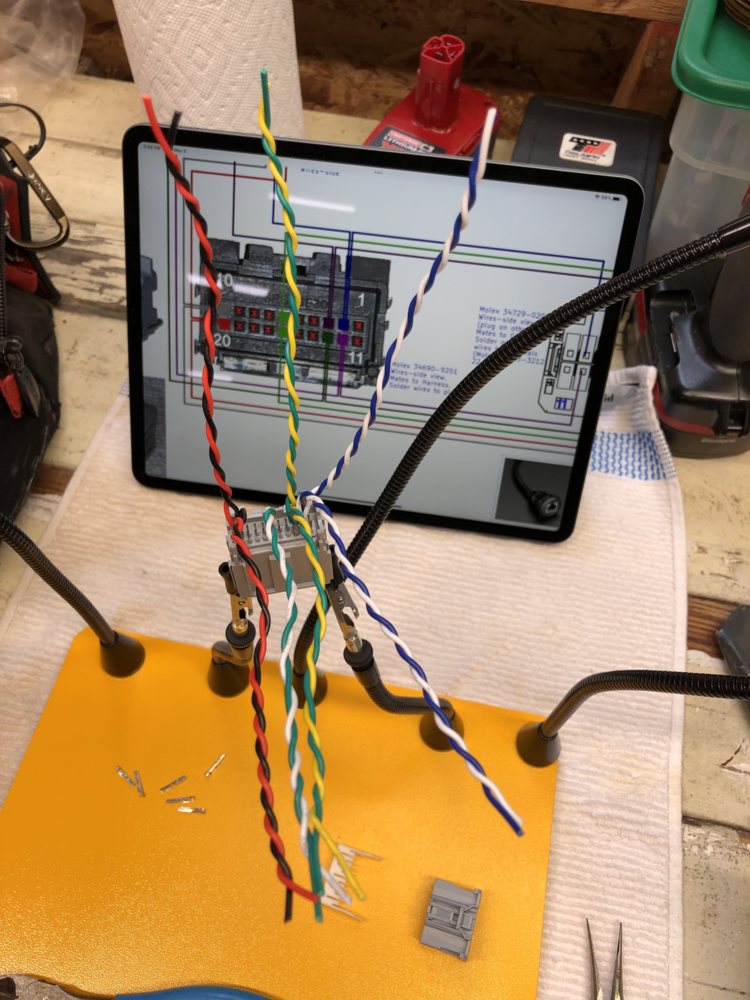

No actives or passive, should be easy for someone versed in this. I had so much trouble drawing a gen-purpose wiring diagram using KiCad that I gave up and went back to gen-purpose drawing tools: PhotoShop circa 2007, and SnagIt! Editor circa 2016. I thought KiCad would be an appropriate tool, but it's not for what I wanted to do. Then I found actual bugs in the UI and got sent down the usual rabbit hole of free software: bug reports, which will likely sit unhandled for years until all the principals have moved on and the the code's been refactored so many times that nobody knows where to start anymore.